Sample Processing

Sample processing tools in the facility include film deposition, heat treating in air or controlled atmospheres, manipulating samples in glove boxes, and sample bonding, cutting, polishing, cleaning, and pressing.

Deposition

Thin film deposition can be performed by evaporation in the Varian Thermal Bell Jar Evaporator or by physical vapor deposition (PVD) in the Sputtering Deposition System. Films can also be made using the Laurell WS400A Spin Coater, the KSV-NIMA-KN4010 Dip Coater, or the KSV-NIMA-KN2002 Langmuir-Blodgett Trough.

Langmuir-Blodgett Trough

Primary staff: Mark Pfeifer

Location: Bard Hall B47

The KSV NIMA Langmuir-Blodgett (LB) trough with dipping capability can be used to create a monolayer film floating on an appropriate liquid sub-phase, and transfer that film to a substrate. The LB trough has a sensitive force balance and moveable barriers that can maintain the surface pressure of a monolayer as the substrate is withdrawn from the trough with the monolayer at its surface. The maximum substrate size is 56 mm high, 52 mm wide, and 3 mm thick. The sub-phase volume in the trough is 176 mL. The force balance can sense a surface tension of up to 150 mN/m with a resolution of 4 μN/m. Substrates can be dipped in either a vertical or horizontal geometry. The LB trough can also be used without the dipper for a variety of experiments where monitoring and control of surface pressure of monolayer films is needed, such as enzyme kinetics or monolayer hydrolysis.

Dip Coater

Primary staff: Mark Pfeifer

Location: Bard Hall B47

The KSV NIMA multi-vessel dip coater uses a programmable, rotating dipper allowing up to eight vessels of solution for cleaning, multiple solution deposition cycles and rinse sequences. The dip coater can accommodate samples up to 50 g in mass, 70 mm high, 45 mm wide, and 3 mm thick. The standard vessel contains 100 mL, but different size vessels can be accommodated.

Sputtering Deposition System

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark Hall D21

Cryo-pumped sputter system with base pressures in the 10-6 Torr range. Three magnetron sources allow sequential or simultaneous deposition from pre-fabricated 2" targets of metals or insulators via DC or RF power. Argon is used for basic depositions, and oxygen and nitrogen are available for reactive sputtering of oxide and nitride films. Stages are available for substrate rotation or substrate heating to ~500°C. Deposition thickness and rate are monitored with a quartz crystal microbalance.

We have a large selection of metal targets and a smaller selection of insulators available for use; please inquire with facility staff for specific questions. Additional targets can be purchased for new processes.

Varian Thermal Bell Jar Evaporator

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark Hall D21

Cryo-pumped thermal evaporator with base pressures in the 10-6 Torr range. Source materials are melted by resistive heating in metal evaporation boats or ceramic crucibles. Three electrodes allow sequential deposition of up to three materials in one vacuum cycle. Evaporation rates are manually controlled by varying the output power of a DC power supply, allowing for currents up to 200 amps. Deposition thickness and rate are monitored with a quartz crystal microbalance. A variety of sample sizes can be accommodated at varying source-to-substrate distances.

Laurell WS400A Spin Coater

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark Hall D21

Laurell WS-400A-6NPP-LITE single wafer spin coater for spinning a variety of substrate sizes from 0.5″ to 6″ diameter up to 6000 rpm for deposition of polymer (from solution) or nanoparticle (from suspension) films. EH&S Fume Hood Safety training is required for use.

Heat Treatment

Heat treating can be performed in ovens or furnaces, in vacuum or gas atmospheres. Available gases include nitrogen, argon, 6% H 94% N, 6% H 94% Ar, CO2. Maximum furnace temperature is 1700°C.

Ovens

Primary staff: Kevin Silverstein; secondary: Mark Pfeifer

Location: Bard Hall B55

The MTI Vacuum Oven has a maximum temperature of 200°C and lowest vacuum pressure of 1 mTorr.

Primary staff: Steve Kriske; secondary: Alicia Tripp

Location: Clark Hall D21

The Hotpack Vacuum Oven has a maximum temperature of 280°C and lowest vacuum pressure of ~1 Torr.

Controlled Atmosphere Furnaces (Bard Hall)

Primary staff: Kevin Silverstein, Mark Pfeifer

Location: Bard Hall B55

Bard Hall has several tube furnaces and gases available:

LabTemp Tube Furnace 1700°C

Lindberg Tube Furnace 1000°C

Across Tube Furnace 1200°C

Carbolite 1600°C Vacuum Tube Furnace: 1E-5 mbar maximum vacuum

Vacuum and Air Furnaces (Clark Hall)

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark Hall D21

Clark Hall hosts several air furnaces and a high-vacuum tube furnace.

Lindberg High Vacuum Furnace: 1100°C maximum temperature, ~10-7 torr base pressure, large 120mm diameter tube

Vulcan 3-550 Box Furnace 1100°C: 550 cubic inches volume

Vulcan 3-1750A Box Furnace 1100°C: 1750 cubic inches volume, air circulation

Inert Atmosphere Glove Boxes

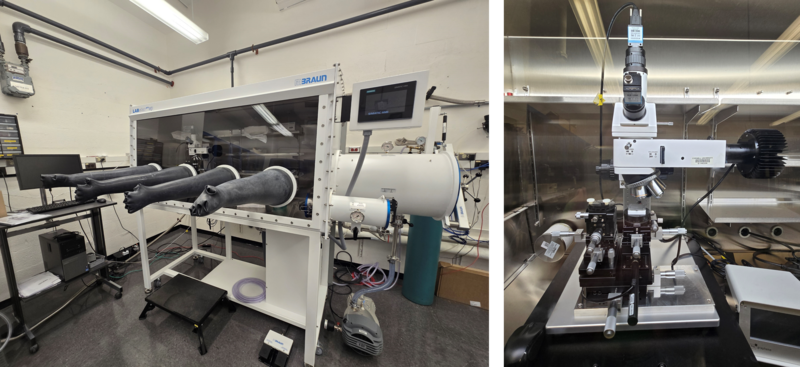

MBraun General Use Glove Box

Primary staff: Steve Kriske; secondary: Alicia Tripp

Location: Clark Hall D21E

Argon inert gas glove box with standard and large antechambers, oxygen sensor, and electrical feed-throughs. Suitable for processes involving solvents.

Labstar Pro Inert Glovebox with HQ Graphene 2D Material Transfer Station

Primary staff: Alicia Tripp; secondary: Steve Kriske

Location: Clark Hall D10

Argon inert 4-glove glove box with standard small and large antechambers. This is a dry box and is kept at <0.1 ppm for both water and oxygen. The box houses a HQ Graphene manual 2D material transfer station complete with vacuum sample holder, temperature control, and microscope. The x, y, tilt, and rotation stages are manually controlled, but the z-stage is motorized.

Tools for Bonding, Cutting, Polishing, Cleaning, and Pressing

Wire Bonders

Primary staff: Steve Kriske; secondary: Alicia Tripp

Location: Clark Hall D22

- Westbond 747630E manual bonder: Wedge bonding with 25 µm aluminum wire, 45° access tool, low force settings available

- TPT HB-05 manual bonder: Wedge bonding with 33 µm aluminum wire (can also be configured with gold wire and ball bonding), 90° access tool, sample heating available

Both bonders can store a large number of buffers/programs with bond parameters in internal memory.

Spot Welders

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark Hall D22

The Branson spot welder can be used to spark-weld thin metal sheets and wires such as thermocouples.

Cutting and Polishing

Tools for cutting and polishing can be used for sample preparation, including preparation for electron microscopy. Click here for the full list located under Sample Preparation Tools.

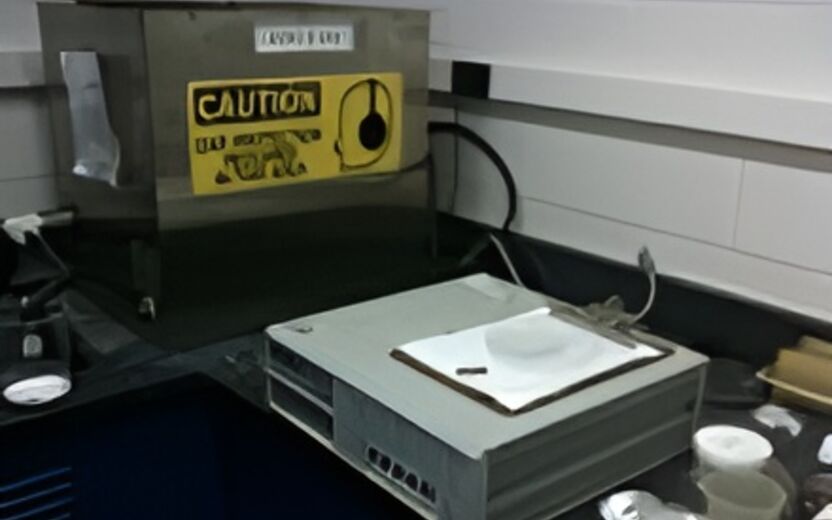

Physical Cleaning

Primary staff: Steve Kriske; secondary: Alicia Tripp, Jon Shu

Location: Clark Hall D21

Physical sample cleaning or surface roughening can be performed with abrasive units (blasting with sand or other media), the SS White sand blasting unit, or ultrasonic baths. The SS White sand blasting unit can also use a pen-style blaster to etch/drill holes through hard materials like glass or ceramics.

Presses

Carver 25 ton press

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark Hall D21

Has a built-in hydraulic system with a clamp force to 25 tons.

Enerpac 10 ton press

Primary staff: Mark Pfeifer; secondary: Kevin Silverstein

Location: Bard Hall B55

Has a built-in hydraulic system with a clamp force to 10 tons. Used for pelletizing, destructive testing, fluid extraction and pressure forming.