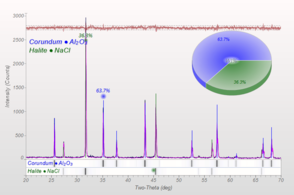

X-ray Diffraction

The CCMR has a suite of X-ray diffraction tools to probe materials for atomic structure. Diffraction patterns of powders or solid samples can be compared to an extensive database. Our instrumentation can provide sample information such as mixed mineral contents, atomic phase of metals or ceramics, microstructure sizes and strains, and more.

The Bruker D8 Advance ECO Powder Diffractometer can quickly measure powder samples and the X-ray diffraction patterns from any powder particles aligned to enable diffraction. Spectra can be used to identify materials and phases, and peak locations and widths can be used to calculate strain and mean crystallite sizes (< 100nm). The instrument uses a Cu K-alpha X-ray source which is not suitable for samples with significant Fe content. Typical sample volumes are greater than 80 µL of powdered material, with domain sizes less than 300 microns.

Bruker Powder Diffractometer

Primary staff: Mark Pfeifer; secondary: Kevin Silverstein

Location: Bard Hall SB56

The Bruker D8 General Area Detector Diffraction (GADDS) System is a versatile diffractometer which can be used to readily survey polycrystalline samples with unknown partial orientation (known as texture) and spatial variation. Standard operation of the GADDS uses Cu K-alpha radiation and can occasionally be switched to a Cobalt source to eliminate noise from Fe-bearing samples.

GADDS

Primary staff: Mark Pfeifer; secondary: Kevin Silverstein

Location: Bard Hall SB56

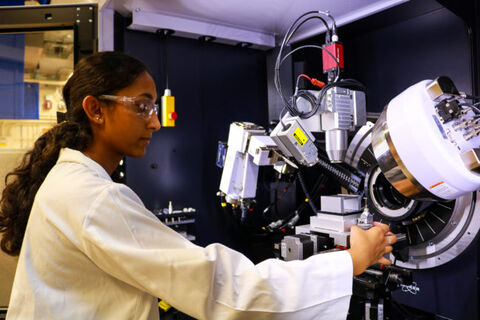

The Rigaku SmartLab X-ray Diffractometer can perform a number of measurements due to the various instrument capabilities with interchangeable stages and optical components. This instrument enables you to obtain automated X-Y mapping of wafers, full pole figures, texture analysis, measurements up to 1100°C in air or in vacuum, rocking curves, crystal quality measurements, stress measurements, and more.

Rigaku SmartLab

Primary staff: Mark Pfeifer; secondary: Kevin Silverstein

Location: Bard Hall SB56

The Rigaku SmartLab has technology that allows both focusing geometry and parallel beam geometry without changing optical components. Interchangeable stages and optical components permit a large range of X-ray techniques to be performed on this instrument.

Capabilities:

- X-ray reflectivity measurements for thin film thickness, roughness and density determinations

- Full pole figures and phi scans for crystallographic texture analysis; high temperature XRD scans up to 1100°C in air or in vacuum

- High-resolution rocking curves for film and crystal quality measurements

- Automated X-Y mapping of wafers

- Stress measurements

- Grazing incident angle diffraction for polycrystalline thin film

The Multiwire Back-Reflection Laue detector is ideal for single crystal samples. The instrument will allow you to determine if a sample is a single crystal or not, and if so the orientation of a crystal surface relative to a primary crystallographic direction can be determined to within 0.2 degrees.

Laue Detector

Primary staff: Mark Pfeifer; secondary: Kevin Silverstein

Location: Clark Hall E1

The Laue instrument is used to orient single crystals, from 1 mm to 1 m in diameter. It is also used to determine whether or not samples are single crystals. The orientation of a crystal surface relative to a primary crystallographic direction can be determined to within 0.2 degrees. The heart of the MWL110 system is a multiwire proportional chamber with a 30 cm x 30 cm active area. The detector is equipped with a selection of four interchangeable collimators (0.5, 1.0, 2.0, and 3.0 mm), a fail-safe X-ray shutter, and a gas delivery system.