Material Properties (Mechanical, Electrical, Magnetic, Thermal)

The Shared Facility offers many characterization tools to identify material properties and performance.

Mechanical Characterization

Study how materials deform with varying forces and temperatures. A dynamic mechanical analyzer and extensional or shear rheometers can be utilized. Materials can be characterized thermomechanically and for coefficients of thermal expansion with a thermomechanical analysis system.

TA Instruments DMA Q800 Dynamic Mechanical Thermal Analysis (DMTA)

Primary staff: Kevin Silverstein; secondary: Mark Pfeifer

Location: Bard Hall B56

Provides time, temperature and frequency domain mechanical analysis of materials as well as static mechanical testing such as tensile and compressive analysis. It can also be used for transient testing such as creep and stress relaxation. Available geometries include: tension, shear, compression, three-point bending, and dual cantilever. The DMA is very similar to the DHR3 Rheometer but for stiffer materials.

TA Instruments Q400EM Thermomechanical Analysis (TMA)

Primary staff: Mark Pfeifer; secondary: Kevin Silverstein

Location: Bard Hall B56

Provides high-precision measurements of material dimension changes as a function of temperature, time, or force. Measures coefficient of thermal expansion (CTE) and heat distortion temperature (HDT), dynamic TMA, and modulated TMA.

TMA specifications:

- Sensitivity: ±100 nm,

- Loading 0.001 to 1.0 Newton

- Dimension change sensitivity: 15 nm

- Heating rate: 0.01 to 50°C/min

- Test atmosphere: air or Nitrogen

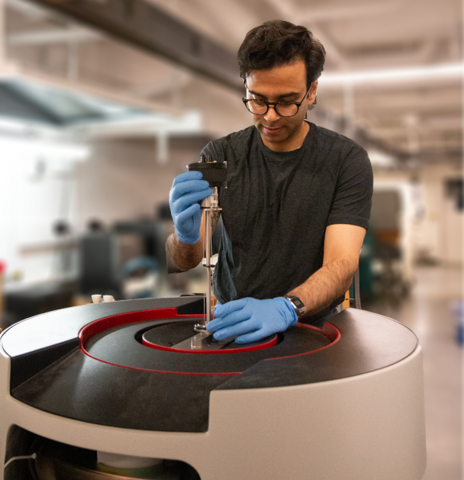

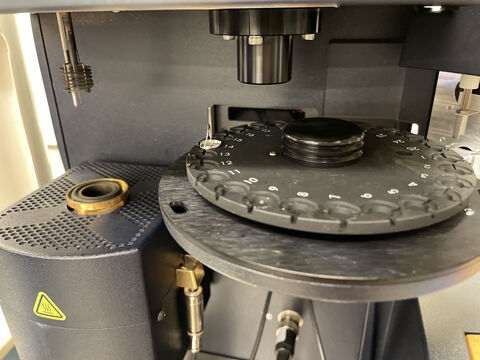

DHR3 Rheometer

Primary staff: Kevin Silverstein; secondary: Mark Pfeifer

Location: Bard Hall B56

The DHR3 can be used to measure: viscosity, shear stress, storage and loss modulus, strain, and phase angle – with respect to: time, temperature, shear rate and frequency. It can also be used for transient testing such as creep and stress relaxation, and UV cure kinetics. Available geometries include: 40 mm parallel plate, 25 and 40 mm 2° cones, and cup and rotor with options of vaned or conical rotor. It has three heating system options, Peltier plate, Peltier concentric cylinders, and an environmental test chamber.

Thermo Fisher Capillary Breakup Extensional Rheometer (CABER)

Primary staff: Kevin Silverstein; secondary: Mark Pfeifer

Location: Bard Hall B56

Extensional rheology is an important component to understanding the behavior of viscoelastic fluids in many processes including: electrospinning, nozzle flow, biaxial tension, blow molding, droplet formation, adhesives, and food. Extensional viscosity is an intrinsic property and cannot be measured through shear rheology. Many materials that show little difference in shear rheology may show drastic differences in extensional rheology. The Capillary Breakup Extensional Rheometer (CaBER) achieves extensional flow by placing a fluid between 2 plates, the plates are then rapidly separated creating a filament. The flow in the filament, driven by surface tension, forces the material into extensional deformation. Understanding of the evolution of the filament with respect to time and the surface tension of the material allows extraction of intrinsic extensional properties.

CABER Specifications:

- Plate diameters, 4, 6, and 8 mm

- Shear viscosity range, 10 to 10e6 s-1

- Strain rate range, 0.01 to 300 s-1

- System response time, 10 ms

- Filament diameter resolution, 8 µm

Micro Hardness Tester

Primary staff: Mark Pfeifer; secondary: Kevin Silverstein

Location: Bard Hall B56

Indentation measuring modes include Vickers, Knoop and Brinell. Ideal for testing on a wide range of materials, including plating. Rigid construction minimizes compliance errors and an internal memory retains 999 tests. A highly stable load mechanism ensures accurate positioning. Once the load is selected automatic testing begins, including loading, holding and releasing, for highly magnified measurements. Upon completion the turret revolves automatically; switching position from the indenter to an optical microscope. Repositioning accuracy is <0.5 micron. The standard incorporated microscope includes 10X and 40X total magnifications. Loads range from 9 to 20000 millinewtons.

Electrical and Magnetic Characterization

Utilize probe stations or Physical Property Measurement Systems (PPMS) to investigate the electrical and magnetic properties of your samples. A PPMS allows a wired sample to sit in a temperature-controlled chamber with the option of applying a magnetic field, allowing a researcher to probe a vast parameter space of temperature, magnetic field, and electrical excitation. Additionally, custom probes can enable other types of measurements such as optical, thermal transport, etc. For higher sensitivity magnetic measurements, our Quantum Design MPMS-3 SQUID System can be used. There are also room temperature probe stations for quick thin film resistance or other measurements.

PPMS and MPMS Systems:

Quantum Design DynaCool PPMS

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark D21

Quantum Design 9T "Red" PPMS

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark D22

Quantum Design 14T "Blue" PPMS

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark D22

Quantum Design MPMS-3 SQUID Magnetometer

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark D19

Probe Stations:

Lakeshore Cryogenic Probe Station

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark D10

Probe station for probing with up to 4 probes (DC or RF up to 40 GHz). The TTP4 probe station (Lakeshore-Tabletop-Magnetic-Cryogenic-Probe-System) accepts a 50 mm or smaller sample with 4 probes. System is turbo pumped to ~10-3 Torr. Probes are viewed via high-resolution microscope (10:1 zoom, 3 micron ultimate resolution), CCD camera and color monitor. Measurement instrumentation normally kept with the system includes Agilent B1500A Device Analyzer for I-V and other SMU-based measurements. Cryostat with Lakeshore controller for low temperature operation and integrated heater for 4-350 K temperature range with 0.05 K temperature stability. Cooling is performed with constant flow of liquid nitrogen or helium (EH&S cryogen safety training required) and the sample shield and probes are cooled via the cryostat.

Cascade CP06 Four Point Probe Setup

Primary staff: Steve Kriske; secondary: Jon Shu

Location: Clark D10

Four-point probe with four in-line spring-mounted probe tips (spacing = 1/16″), vacuum chuck, Keithley 2400 source meter and data acquisition computer for quick measurements of thin film or bulk resistance and calculation of resistivity or sheet resistance.

Thermal Analysis

Study how a material behaves or degrades with temperature. If you need to know the thermal stability and moisture content of your material, you might use the TA Instruments 5500 Thermogravimetric Analyzer (TGA). If you need to quantify polymer crystallinity, then you may use the TA Instruments DSC Auto 2500 Differential Scanning Calorimeter (DSC) to get glass transitions and melting points.

TGA

Primary staff: Dimitrios Koumoulis; secondary: Alicia Tripp

Location: S.T. Olin B78

DSC

Primary staff: Dimitrios Koumoulis; secondary: Alicia Tripp

Location: S.T. Olin B78